Bimetal Technology: strenght and performance with Tokat®

At Kugler Bimetal, our technology is based on the casting process, with which Tokat® bronze is molten and cast into a metallic substrate. This technique ensures a homogeneous metallurgical bond between the substrate and Tokat®, providing optimal strength and durability for our bimetallic products.

Start your project with us

Do you have a question or a new project to discuss about ?

Synergy of Strength and Durability

The main advantage of our approach lies in combining the mechanical properties of steel with the specific characteristics of the alloys used, such as resistance to wear, corrosion, and high temperatures. This synergy allows us to offer customized solutions tailored to the most demanding application requirements.

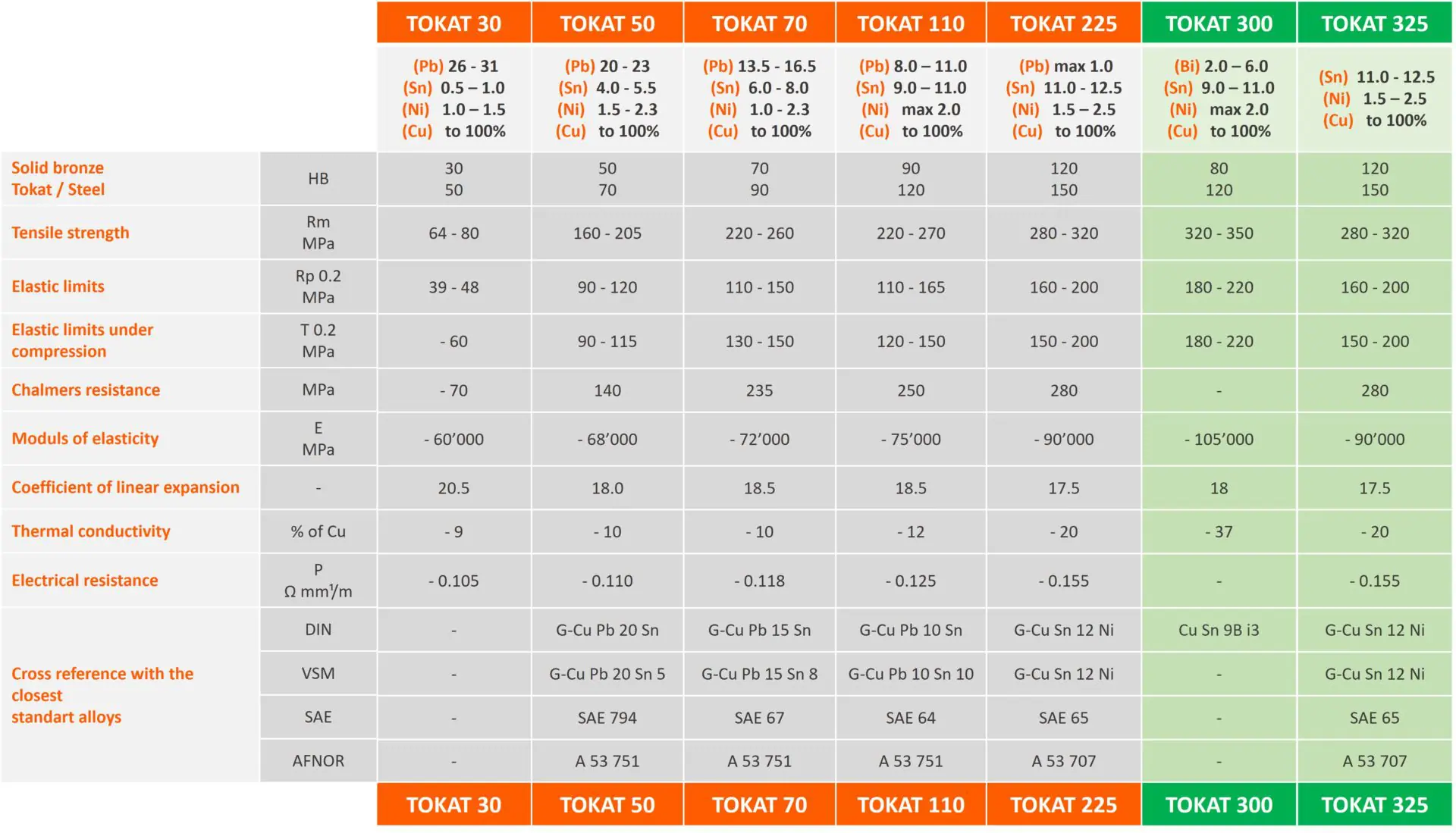

Characteristic of alloys

Tokat® is a patented technology developed by Kugler Bimetal that enables durable bimetallic bonding without the use of adhesives or mechanical fasteners. This innovation is based on a direct metallurgical fusion, providing excellent resistance to wear, heat, and high mechanical stresses. Tokat® significantly reduces the coefficient of friction compared to traditional alloys, thereby improving system efficiency and extending the lifespan of components. It offers strong technical performance, particularly through its ability to operate under extreme conditions, maintain long-term mechanical stability, and withstand high loads while ensuring optimal equipment reliability. It is a high-performance engineered bronze specifically optimized for demanding applications.