Laser Technology: A Driver of Innovation at Kugler Bimetal

At Kugler Bimetal, innovation is not limited to material composition, it also encompasses advanced transformation processes. The integration of cutting-edge laser technologies is a key focus within our R&D strategy, allowing us to address complex technical challenges with precision and efficiency.

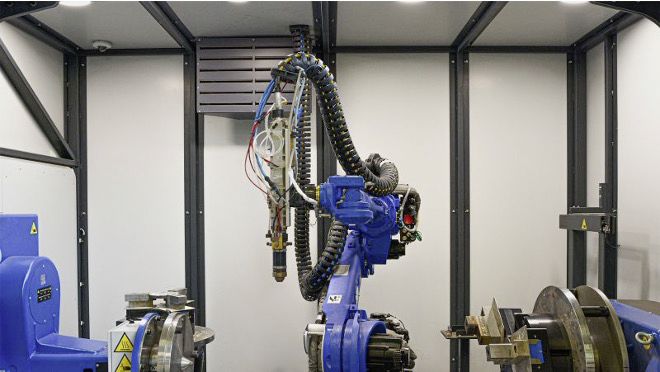

Laser Precision at the Heart of Manufacturing

One of the key advantages of laser technology is its ability to process metals with extreme accuracy whether through welding, cladding, or cutting. Using highly concentrated energy beams, we can locally modify the surface or structure of a material without compromising its core integrity.

At Kugler Bimetal, laser-based processes are being explored in several high-value applications, particularly in:

- Aerospace, where reducing component weight without compromising performance is crucial

- Surface enhancement of metal bearings

- Restoration and reuse of high-performance components to extend their service life

Focus on the SPACEBEAR Project

As part of the SPACEBEAR project, in collaboration with Fraunhofer IWS and GFE, we have been testing advanced laser cladding techniques on titanium-based bearings.

The objective is to develop lighter aerospace solutions that maintain optimal tribological performance.

Laser-based surface treatments offer:

- Significant weight reduction of components (up to 40%)

- Strong bonding between metallic layers

- High customization of surface properties according to thermal or mechanical requirements

Towards Cleaner and More Efficient Production

Laser technology also supports our environmental goals:

- Less material waste due to ultra-precise cutting

- Reduced need for mechanical tooling, lowering maintenance and energy consumption

- Cleaner, contactless processes that align with sustainable manufacturing principles