Friction is essential in our daily lives, impacting everything from walking and driving to holding objects and even having fun sliding down snowy slopes. Put simply, friction is a force that opposes motion between surfaces in contact.

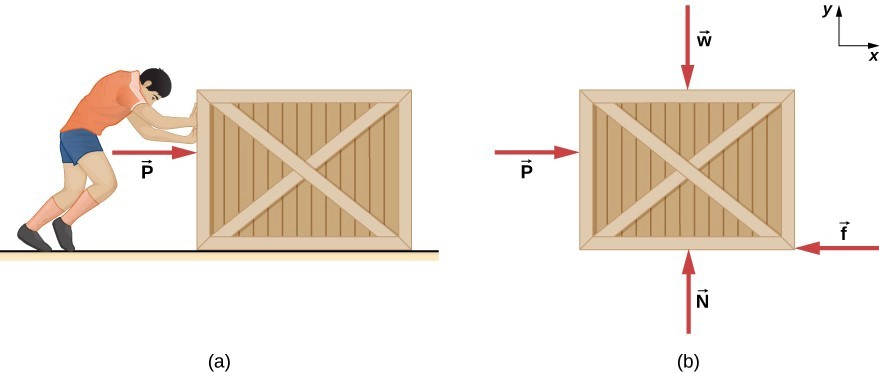

When two surfaces meet, friction comes in two main forms: static and kinetic. Static friction is what resists movement when an object is stationary, as when you and a friend try to push a heavy object across the floor. Kinetic friction, on the other hand, is what keeps opposing the motion once the object is moving—notice how it’s easier to keep it sliding once it starts going?

In this article, we’ll focus on kinetic (or sliding) friction, which is especially relevant for the mechanical components we manufacture. In mechanical systems, kinetic friction is both a help and a hindrance. While high friction is desirable in parts like brakes and clutches, it causes power losses and reduces efficiency in gearboxes, pumps, compressors, and other machinery.

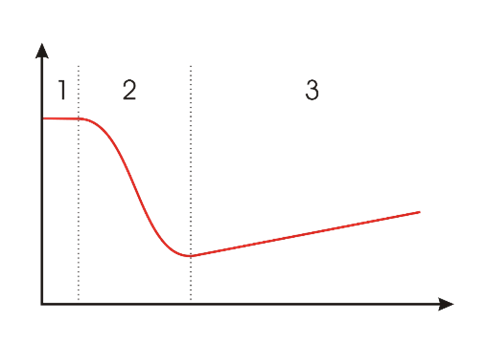

At Kugler Bimetal, our solutions are primarily used in hydrodynamic systems. This means that under normal operating conditions, a lubricating oil film keeps parts like shafts and bearings separated, reducing wear. But, as in life, things aren’t always perfect. When the oil film breaks down or hasn’t yet fully formed, parts come into direct contact, leading to friction that can cause power losses. This is represented by the Stribeck curve below, where you can see the boundary and mixed film lubrication regimes, followed by the hydrodynamic lubrication condition. Boundary and mixed film lubrication – this is where Kugler Bimetal’s Tokat materials shine.

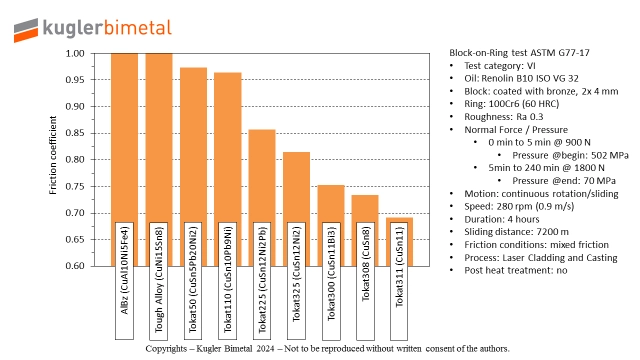

Our products are engineered to minimize friction between moving components. To validate this, we conducted extensive testing using a standardized block-on-ring setup (ASTM G77-17) under oil-lubricated conditions. The test involved a hardened 100 Cr6 steel ring (60 HRC) with a specific surface finish (0.3 Ra) rubbing against a test material block, lubricated by Renolin B10 ISO VG 32, a general-use oil.

For the first five minutes, a force of 900 N was applied, equating to a specific pressure over 500 MPa due to the line of contact or Hertzian pressure. After five minutes, with the start of wear and increased contact area, the force was doubled to 1800 N resulting in roughly 70 MPa by the end of the four-hour test.

The chart below illustrates the relative friction coefficient results. Under these conditions, Tokat 311 displayed a coefficient of friction 67% lower than CuNi15Sn8 (UNS C-96900), known as a tough metal, or aluminum bronze CuAl10Ni5Fe4. Even more impressively, our lead-free alloys reduced friction by 15–30% compared to traditional lead-based alternatives.

If you’re seeking a low-friction, wear resistant lead-free alternative for your components, look no further – Kugler Bimetal has the solution.

In our next article, we’ll cover the wear rate results for this same testing setup.